How Kurt Can Help You Bring Your Die Casting Supply Chain Back to the U.S.A.

In today’s rapidly shifting global economy, more manufacturers are rethinking their supply chains and choosing to bring production back to the United States—a movement known as reshoring. Whether it’s due to rising overseas costs, supply chain disruptions, or a renewed focus on quality and innovation, reshoring has become a strategic imperative for many companies.

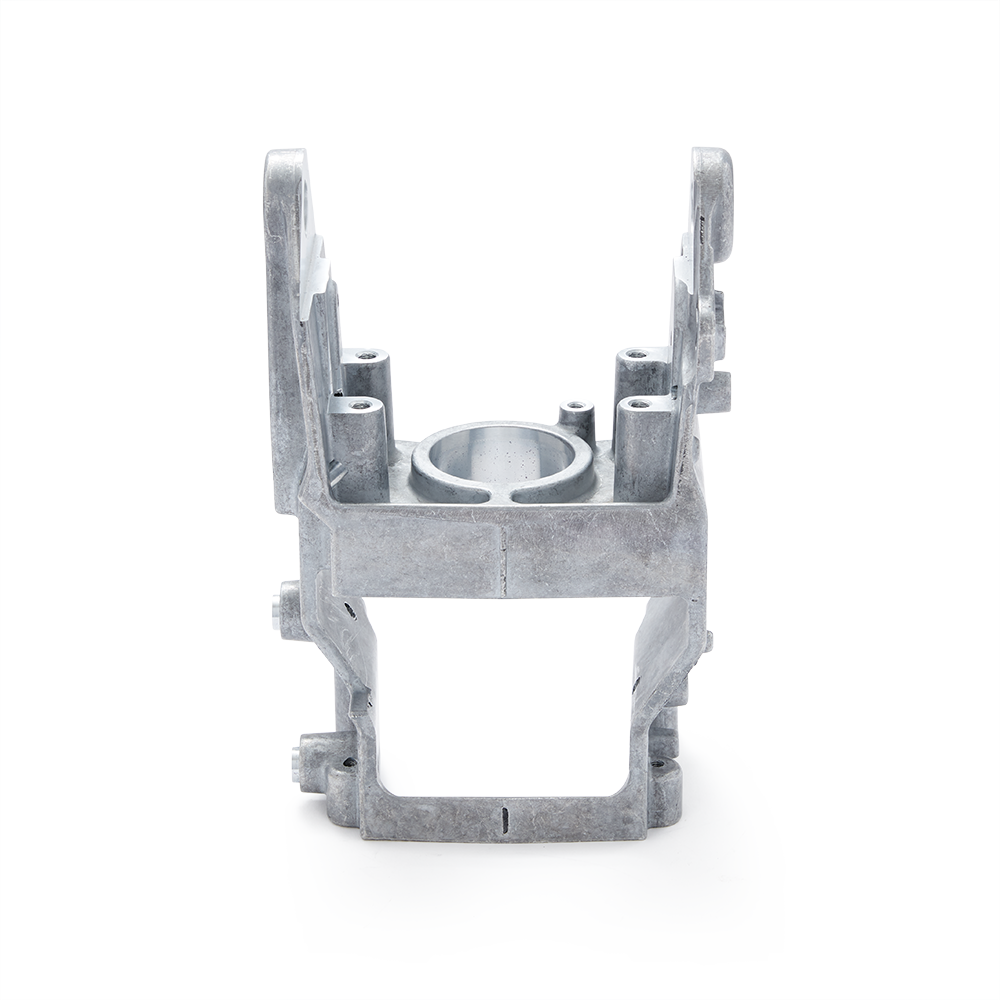

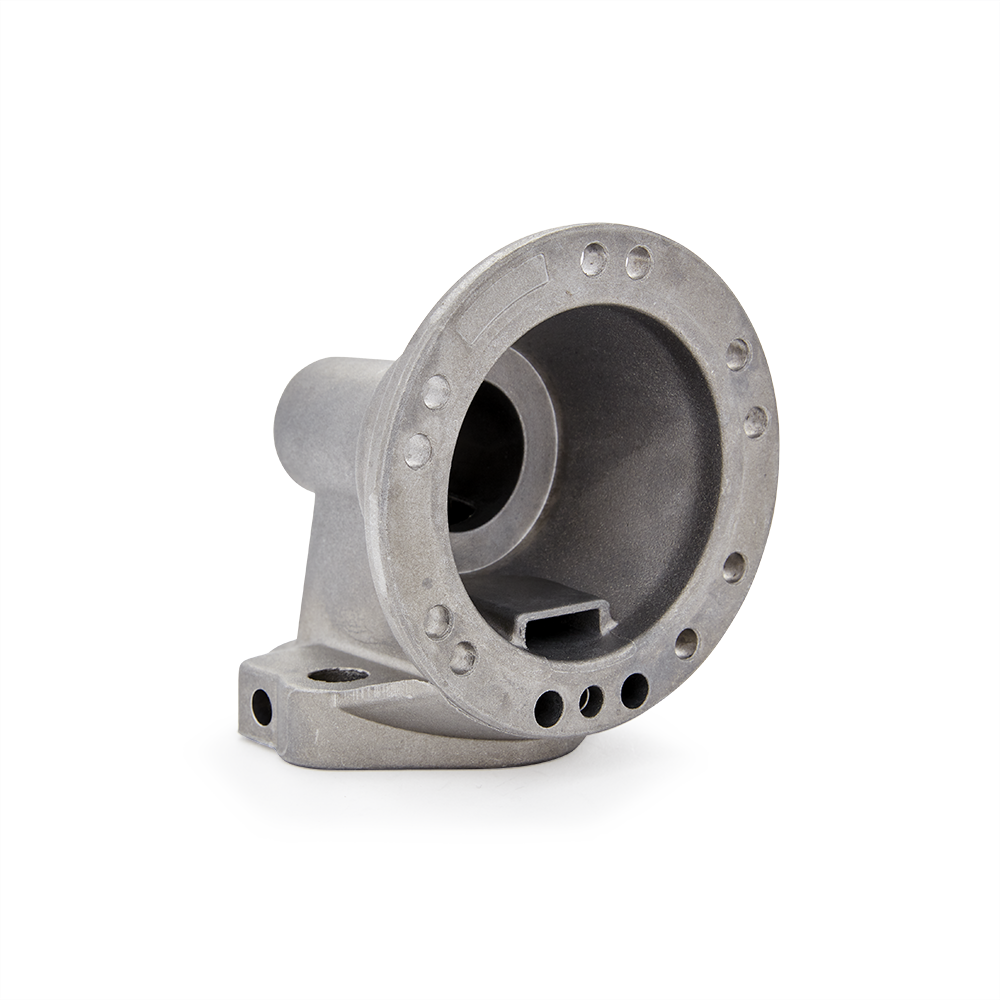

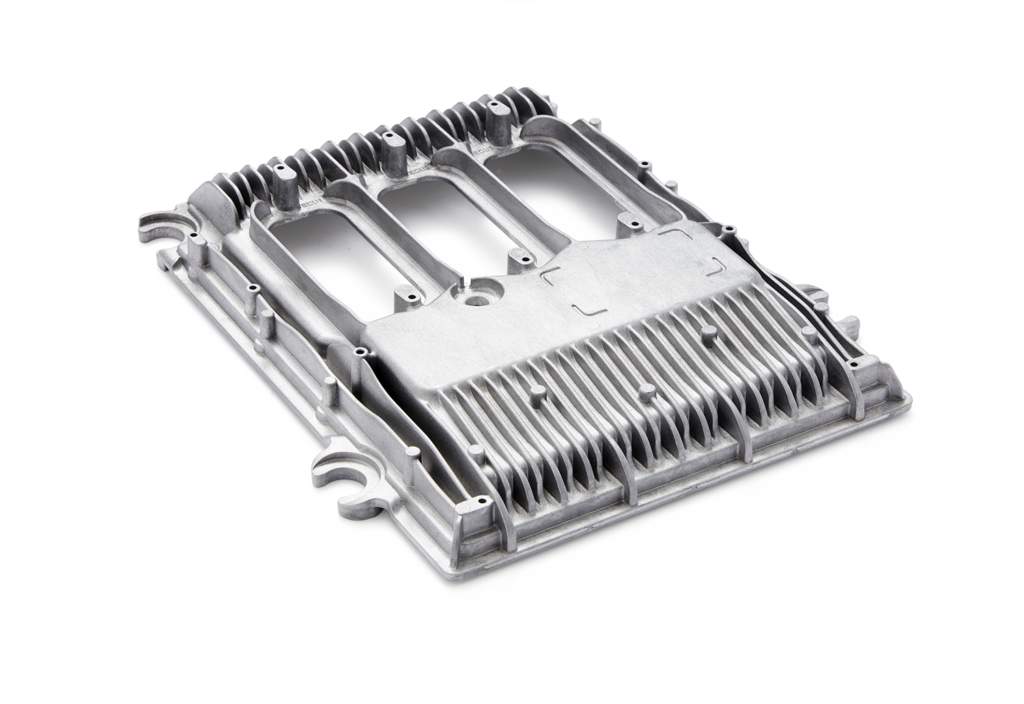

At Kurt Die Casting, we’re proud to be a trusted partner, helping businesses successfully reshore their die casting and machining parts programs. We’ll help you make the transition seamlessly, efficiently, and profitably. Kurt’s Complete Part Solutions allow us to provide design, casting, machining, finishing and inventory management all under one roof, allowing us to be a competitive alternative to foreign sourcing of parts. Learn how we helped a major domestic lighting company streamline their supply chain ->

Why Reshore Die Casting Parts Programs?

Overseas manufacturing once promised low costs and high-volume output, but today’s reality tells a different story. Here are some of the top reasons companies are now considering U.S. Suppliers for their diecasting needs

- Supply Chain Resilience: Shorter, domestic supply chains reduce the risk of delays and disruptions.

- Improved Quality Control: U.S. manufacturing standards and oversight lead to higher, more consistent product quality. Learn more about Kurt Quality ->

- Reduced Total Cost of Ownership: When factoring in logistics, communication, lead times, and rework, reshoring can often result in cost savings.

- Speed to Market: Domestic production enables quicker response times and more agile development cycles.

- Sustainability: Local sourcing reduces carbon emissions and supports more sustainable business practices.

- Intellectual Property Protection: U.S. laws provide stronger IP protections compared to many overseas environments.

How Kurt Makes Reshoring Your Program Easy

As a U.S.-based tight-tolerance manufacturing leader with over 70 years of machining and die casting experience and 4 divisions, Kurt offers unmatched expertise and infrastructure to help U.S. companies bring their manufacturing home.

1. Engineering Support & Design Optimization

We don’t just replicate your current part—we make it better. Our in-house die casting engineering team will collaborate with you to optimize your tooling and part designs, reduce weight, improve performance, and lower costs.

2. State-of-the-Art Facilities with Secondary Processes

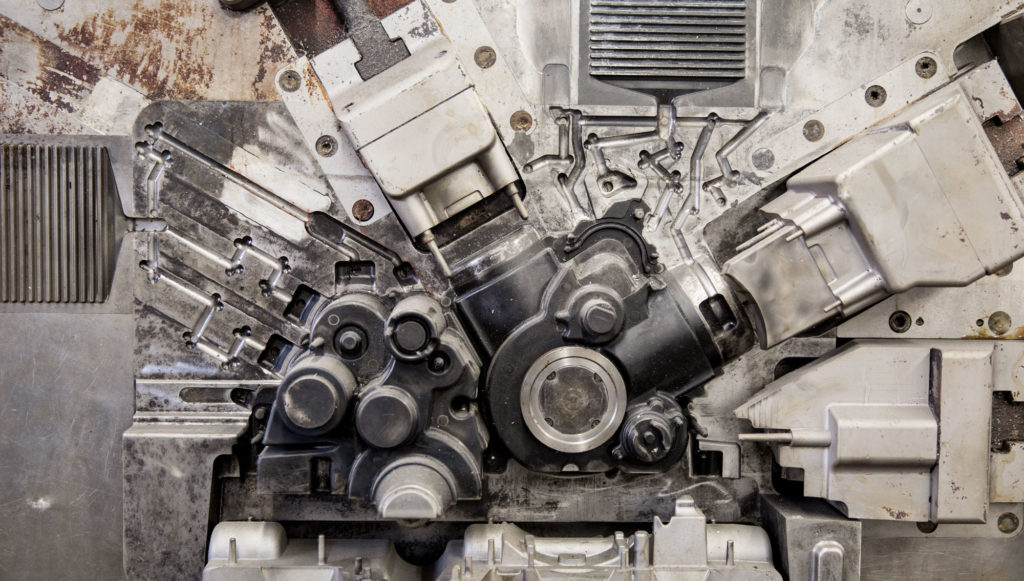

Kurt Die Casting operates from an ISO 9001:2015-certified facility in Minnesota—equipped with advanced die casting machines, CNC machining centers, and finishing capabilities—enabling us to handle everything from low- to high-volume production.

3. Tooling Transfer & Adaptation

Already have tools overseas? We’ll help you assess, transfer, and adapt your existing tooling for use at our U.S. facility—minimizing downtime and cost. If you need new tooling, we can help you design, optimize and create it.

4. Shorter Lead Times, Greater Flexibility

With local production, we can offer significantly shorter lead times and greater flexibility to meet changing demand and design updates.

5. Transparent Communication

Our dedicated project managers keep you informed every step of the way, reducing misunderstandings and ensuring your expectations are met—or exceeded.

6. Kanban Inventory Management

Kurt can offer customers Kanban Inventory Management, a pull system designed to reduce a their on-hand inventory by shipping materials to the customer as needed. When inventory analysis indicates that stock is depleted, the customer notifies us via email, and we ship out the parts from our inventory.

6. Made in the USA, Trusted Worldwide

Kurt is proudly American-made, with a reputation for precision, integrity, and performance that spans across industries—from agriculture to aerospace, medical to industrial equipment.

Ready to Bring It Home?

If you’re considering reshoring your die casting operations, Kurt is ready to help. We understand the challenges, but more importantly, we understand how to solve them. From first conversation to final part, we’re here to make your reshoring journey a success.

Let’s start the conversation. Contact us today to discuss your reshoring project and see how Kurt Die Casting can deliver better quality, faster turnaround, and a stronger domestic supply chain.